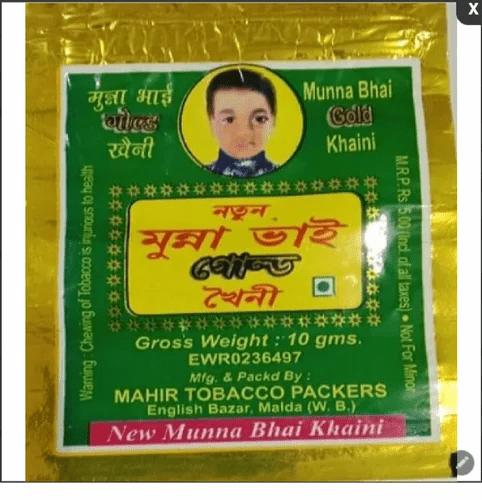

In today’s fast-moving market, plastic pouches are essential. These flexible bags are everywhere, packaging everything from daily snacks and essential medicines to countless other consumer goods. As a leading packaging supplier based in Kolkata, we at Tirupati Traders understand that the growing demand for pouches is driven by their convenience, cost-effectiveness, and ability to keep products fresh. However, the road ahead to 2025 presents a unique set of challenges.

A major shift is happening. More than ever, Indian consumers and businesses are looking for packaging that is kind to the environment. This focus on sustainability is reshaping our industry. This blog explores the key environmental, economic, and consumer-driven challenges that laminated pouch makers will face and offers practical solutions for businesses that rely on high-quality plastic pouch packaging.

The Evolving Landscape of Plastic Pouch Manufacturing

Plastic pouches, from stand-up and gusseted bags to retort pouches, are a cornerstone of modern flexible packaging. While our discussion focuses on plastic pouches, the insights shared here are relevant for the entire flexible packaging sector. Let’s delve into the hurdles and how we can overcome them together.

Challenge 1: The Sustainability Imperative and Embracing a Circular Economy

The push to reduce plastic waste is stronger than ever, coming from both consumers and regulatory bodies. A significant challenge for any custom printed pouch manufacturer is transitioning to recyclable, biodegradable, or compostable materials without compromising the safety and shelf-life of the products inside. Many pouches use multiple layers of different materials, which makes recycling them a complex task for existing infrastructure.

This is where new approaches like Extended Producer Responsibility (EPR) come into play, making manufacturers partners in the recycling process. Additionally, while bio-based plastics from sources like corn or sugarcane are promising, their cost and performance can still be a concern. The solution lies in innovation and responsible design.

Our Solution: Championing Sustainable Materials and Smart Design

- Adopting Eco-Friendly Materials: We are actively exploring and promoting the use of sustainable materials like recyclable polyethylene (PE) and polypropylene (PP). Mono-material pouches, made from a single type of plastic, are gaining traction because they are significantly easier to recycle. These options help businesses meet their green targets without sacrificing quality.

- Designing for Recyclability (DfR): The future of packaging is in smart design. This means creating pouches with thinner films and fewer layers to reduce material usage. We also advocate for using water-based inks and adhesives that are better for the environment. By following DfR principles, we ensure our pouches can be efficiently processed by recycling facilities.

Challenge 2: Volatile Material Costs and Supply Chain Uncertainties

The price of raw plastic can fluctuate dramatically due to global events, supply chain disruptions, and shifts in production capacity. For businesses in the FMCG sector, these rising costs can squeeze profit margins. Finding a consistent supply of high-quality recycled plastic at a stable price adds another layer of complexity. Furthermore, trade policies and tariffs can unexpectedly impact the cost of both raw materials and finished pouches.

Our Solution: Strategic Sourcing and Production Optimisation

To counter market volatility, we work on building strong, long-term relationships with material suppliers, which helps in securing stable pricing. We also believe in diversifying our sourcing network, including local suppliers, to minimise risks. Internally, we adopt lean manufacturing principles to cut down on waste and enhance efficiency. Investing in automation and advanced production software allows us to reduce labour costs and material wastage, passing on the savings to you. For businesses looking for durable and secure packaging, our heat seal laminated plastic pouches offer a reliable and cost-effective solution.

Challenge 3: Keeping Pace with Evolving Consumer Demands

Today’s consumers want it all: packaging that is convenient, functional, and visually appealing. There’s a growing demand for features like resealable zippers, easy-tear notches, and tamper-evident seals. Your product’s packaging is often the first interaction a customer has with your brand, so it needs to be impressive. The challenge is to merge this functionality and aesthetic appeal with sustainability.

Moreover, the rise of e-commerce means packaging must be robust enough to withstand the rigours of shipping. Consumers also value transparency, preferring pouches with clear windows to see the product inside. These evolving preferences require a forward-thinking packaging solutions expert.

Our Solution: Innovation in Pouch Functionality and Design

We invest in research and development to create innovative pouch designs that meet modern consumer needs. With advanced printing technology, we ensure your brand’s message is communicated clearly and vibrantly. Functionality is key, which is why we offer features like zippers, spouts, and ergonomic designs. Explore how our printed snacks packaging combines freshness with powerful brand appeal.

Digital printing also allows for greater customisation, helping your products connect with specific consumer segments. We can even incorporate smart features like QR codes to offer customers an interactive experience with your brand.

Tirupati Traders: Your Partner in Overcoming Packaging Challenges

At Tirupati Traders, we understand the complexities of plastic pouch manufacturing. We are dedicated to providing solutions that address the core challenges faced by businesses across India. We don’t just supply pouches; we deliver peace of mind.

- Ensuring Product Freshness: Many businesses worry about their products spoiling due to poor packaging. Our pouches are engineered with superior barrier properties and secure seals to lock out air and moisture. Our airtight zipper pouches are a perfect example, keeping contents fresh from the first use to the last. This extended shelf life protects your product and your reputation.

- Delivering Strength and Durability: Weak pouches that tear or puncture during transit can lead to significant losses and unhappy customers. We use high-grade, robust materials to construct our pouches. Our plastic laminated pouches are built to withstand tough handling, ensuring your product arrives safely in the hands of your customers.

- Guaranteeing High-Quality Printing: Your packaging is a reflection of your brand. Faded or smeared printing can make a product look cheap and untrustworthy. We utilize state-of-the-art printing technology to produce sharp, vibrant, and durable designs that make your product pop on the shelves. Our custom printing helps your brand tell its story effectively.

- Offering Unmatched Customisation and Value: We know that one size does not fit all. Whether you need a unique shape, size, or feature, we can create a custom pouch tailored perfectly to your product. All this comes at a competitive price, ensuring you get the best value for your investment without compromising on quality.

Ready to find the perfect pouch for your product? Tirupati Traders manufactures and exports plastic pouches for companies all over India. Call us at +91 70032 13441 to discuss your needs with our experts.

Answering Your Key Questions About the Future of Packaging

Many of our clients, from established FMCG brands to emerging startups, often ask about the road ahead. A common question is about the biggest hurdles for plastic pouch manufacturing. The main challenges are meeting the demand for sustainable packaging, navigating complex environmental regulations, and satisfying consumer desires for both functionality and aesthetic appeal.

This naturally leads to the question of how companies can make their packaging more eco-friendly. The answer lies in a multi-pronged approach: using recyclable or plant-based materials, designing pouches that use less plastic, and collaborating with the recycling industry to improve end-of-life solutions. New technologies are playing a massive role here, with advanced machinery and software enabling more efficient production and the creation of innovative, ‘smart’ packaging features.

When it comes to quality, a robust quality control process is non-negotiable. This means rigorous checks at every manufacturing stage, from raw material inspection to final product testing. As for the future, we believe the most popular pouches will be those that are easy to recycle, lightweight, and offer enhanced features like resealable closures. Ultimately, a great design is crucial—it must be eye-catching, user-friendly, and reflective of your brand’s quality to succeed on a crowded shelf.

The Future is Bright: Adapting to Thrive

The plastic pouch industry is at a pivotal moment. The path forward requires a balance between meeting business needs for reliable, affordable packaging and fulfilling our collective responsibility to the planet. By embracing sustainable materials, optimising production, and driving innovation in design, we can create a future where business growth and environmental stewardship go hand in hand. At Tirupati Traders, we are committed to helping you navigate these changes and providing the high-quality, custom packaging solutions your business deserves.