The Indian market is buzzing with change. The rapid growth of e-commerce, a strong consumer shift towards sustainability, and ongoing labour challenges are transforming how businesses operate. To keep up and lead the pack, companies in the FMCG, pharmaceutical, and agricultural sectors must look towards smarter, more efficient solutions. This is where packaging automation comes in, not as a distant concept, but as a crucial business strategy for 2025 and beyond.

Packaging automation is the use of technology and machinery to streamline the entire packaging process, from filling and sealing to labelling and palletizing. For any business that requires custom, high-quality plastic pouch packaging, automation is the key to unlocking greater speed, unwavering accuracy, and significant cost savings. It moves your operations from manual labour to a system that delivers consistent, professional results every single time. This guide will walk you through the essential automation trends shaping the industry, helping you prepare your business for a more productive future.

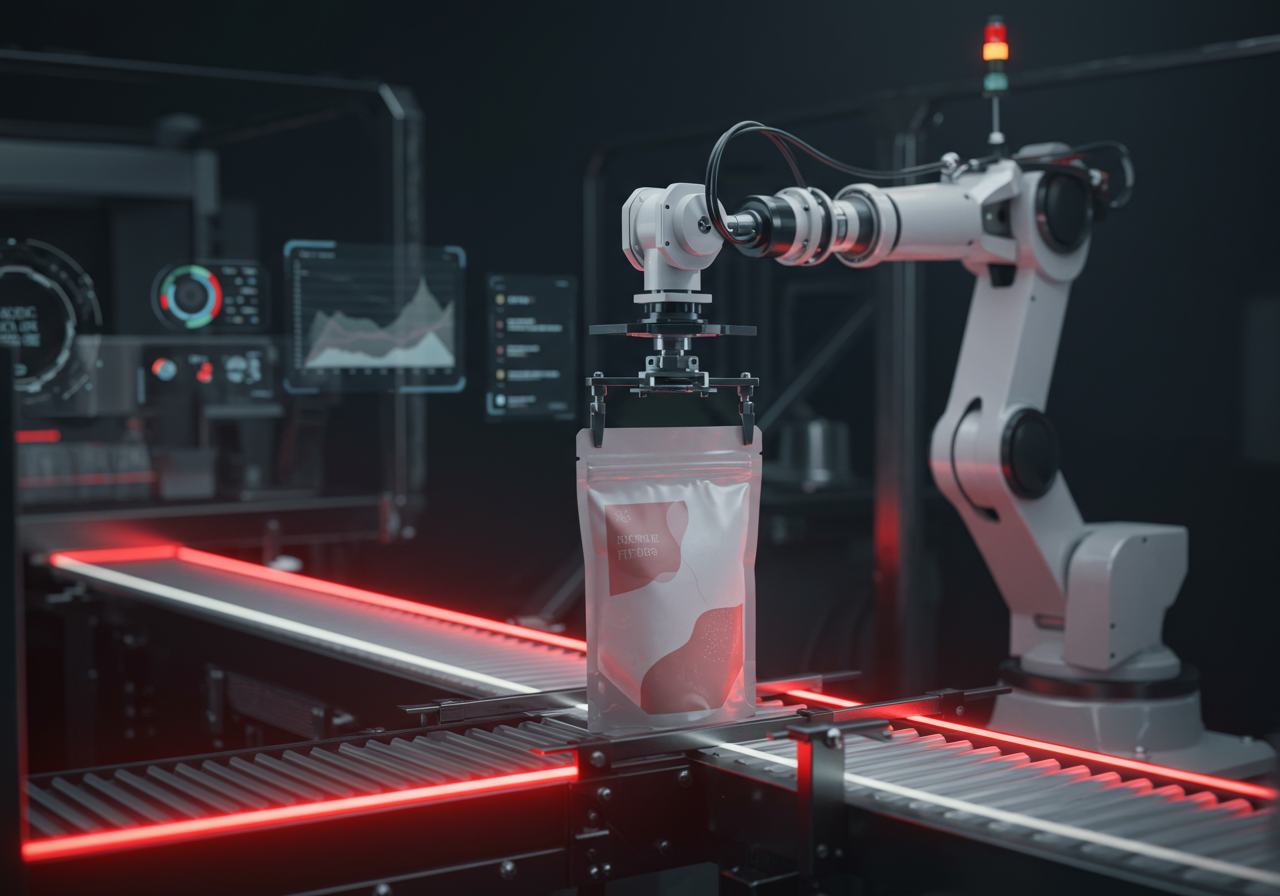

Robotics and Cobots: Your Flexible Workforce is Growing

When we talk about automation, robots are often the first thing that comes to mind. In 2025, they are more accessible and versatile than ever. Robotics in packaging offers incredible speed and precision for repetitive tasks. But the real game-changer for many small and medium-sized businesses in India is the rise of “cobots,” or collaborative robots. These are designed to work safely alongside your human team without needing large safety cages, making them easier and more affordable to integrate into your existing setup.

From picking products off a conveyor belt to placing them perfectly in boxes, modern robots and cobots can handle it all. They are instrumental in primary, secondary, and tertiary packaging stages. For businesses that require specialised solutions like a durable two-layer laminated pouch, robotic systems ensure each pouch is handled correctly, filled accurately, and sealed perfectly, preserving the integrity of both the product and the packaging.

AI and Machine Learning: Making Your Packaging Line Smarter

Artificial Intelligence (AI) and Machine Learning (ML) are the brains behind the new generation of packaging machinery. These technologies are making packaging lines not just faster, but significantly smarter. One of the most powerful applications is in quality control. AI-powered vision systems can inspect every single package on the line, spotting tiny defects, printing errors, or sealing issues that a human eye might miss, ensuring only perfect products reach your customers.

Furthermore, AI plays a critical role in optimisation. It can analyse data from your production line to predict when a machine might need maintenance, preventing costly downtime. For businesses that rely on intricate branding, like those using custom-branded spice powder pouches, AI can ensure print quality and colour consistency across millions of units. This intelligence helps reduce material waste and boosts overall efficiency, directly impacting your bottom line.

Sustainable Packaging Automation: Answering the Call for an Eco-Friendly Future

Today’s consumers are more environmentally conscious than ever, and regulations are following suit. Sustainable packaging is no longer a niche market but a core business requirement. Automation is a powerful ally in this mission. Automated systems are incredibly precise, which means they can “right-size” packaging for each product, drastically reducing material consumption and shipping costs. This precision is vital when working with eco-friendly materials, which can sometimes be more delicate or challenging to handle manually.

Automation directly impacts sustainability by minimising errors and therefore reducing product and material waste. By ensuring every package, like a pouch for pulses, is sealed correctly, you prevent spoilage and waste throughout the supply chain. A reliable packaging supplier like Tirupati Traders can provide materials designed to run smoothly on automated lines, helping you achieve both your production and environmental goals.

The Business Case for Automation: Justifying the Investment

Investing in automation can seem like a significant expense, but it’s crucial to look at the long-term Return on Investment (ROI). The cost of implementing packaging automation varies, but the benefits often quickly justify the initial outlay. Consider the savings from reduced labour costs, the dramatic increase in production speed, and the sharp decline in waste from human error. Automation allows businesses that package high volumes, such as those producing detergent powder packets, to scale up operations without a proportional increase in costs.

To make a sound decision, perform a thorough cost-benefit analysis. Factor in not just the machine’s price but also the savings in materials, the value of improved quality, and the ability to take on larger orders. Many businesses find success by starting small—automating a single bottleneck in their process—and then expanding as they see the positive results.

Partnering for the Future: How Tirupati Traders Supports Your Automation Journey

Embracing automation is not just about buying machinery; it’s about creating a seamless ecosystem where your equipment, materials, and processes work in harmony. As a leading laminated pouch maker in Kolkata, Tirupati Traders understands that the quality of your packaging is fundamental to the success of your automation investment. Custom, high-quality plastic pouch packaging protects your product, extends its shelf life, and serves as a powerful branding tool. Our pouches are engineered for consistency, ensuring they perform flawlessly on high-speed automated lines.

Here’s how our tailored solutions can help you get the most out of your automated systems:

- Consistent and Reliable Materials: Our pouches are manufactured with uniform thickness, size, and material properties, which is critical for preventing jams and ensuring smooth operation in automated filling and sealing machines. This reliability is essential whether you’re packaging leak-proof edible oil or delicate food items.

- Customisation for Automation: Automation excels with standardisation, and we can help you create the perfect custom pouch that is also perfectly suited for machinery. We work with you to design pouches, like our freshness-sealed bread packaging, that meet your branding needs while being optimised for automated handling, filling, and sealing.

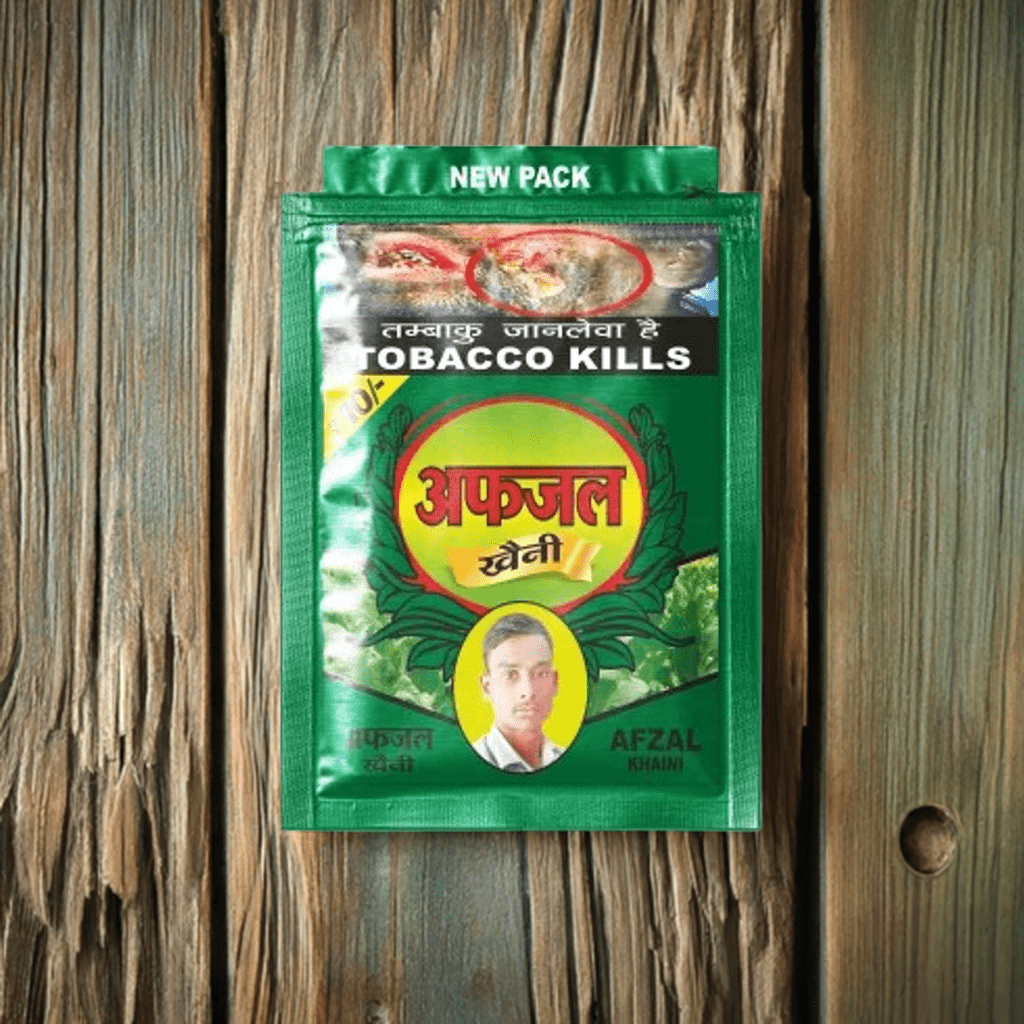

- Diverse Solutions for Every Industry: We offer a vast range of products designed for durability and performance. From our moisture-resistant Khaini pouches to hygienic sanitary pad pouches, each product is made with the highest quality standards, ensuring they protect your product and enhance your brand.

Are You Ready for Packaging’s Next Chapter?

The trends for 2025 are clear: the future of packaging is automated, intelligent, and sustainable. For Indian businesses, this is a golden opportunity to enhance efficiency, improve product quality, and compete on a larger scale. By understanding these technological shifts and partnering with an expert custom printed pouch manufacturer like Tirupati Traders, you can ensure your business is not just ready for the future, but is actively shaping it.

The journey towards automation is a significant step, but one that promises immense rewards. Are you ready to make your packaging operations smarter, greener, and more efficient? Explore our packaging solutions and let’s build the future together.