Have you ever wondered how the vibrant, sturdy pouches holding your favourite snacks, spices, or daily essentials are created? For many FMCG brands, retailers, and traders across India, the answer lies in a powerful manufacturing process known as plastic extrusion. This technology is the backbone of the flexible packaging industry, turning simple plastic granules into high-performance pouches that protect, preserve, and promote products on crowded shelves.

As a leading packaging supplier in Kolkata, Tirupati Traders leverages this process to deliver top-tier packaging solutions. Let’s delve into how plastic extrusion works and why it’s indispensable for your business.

What Exactly is Plastic Extrusion?

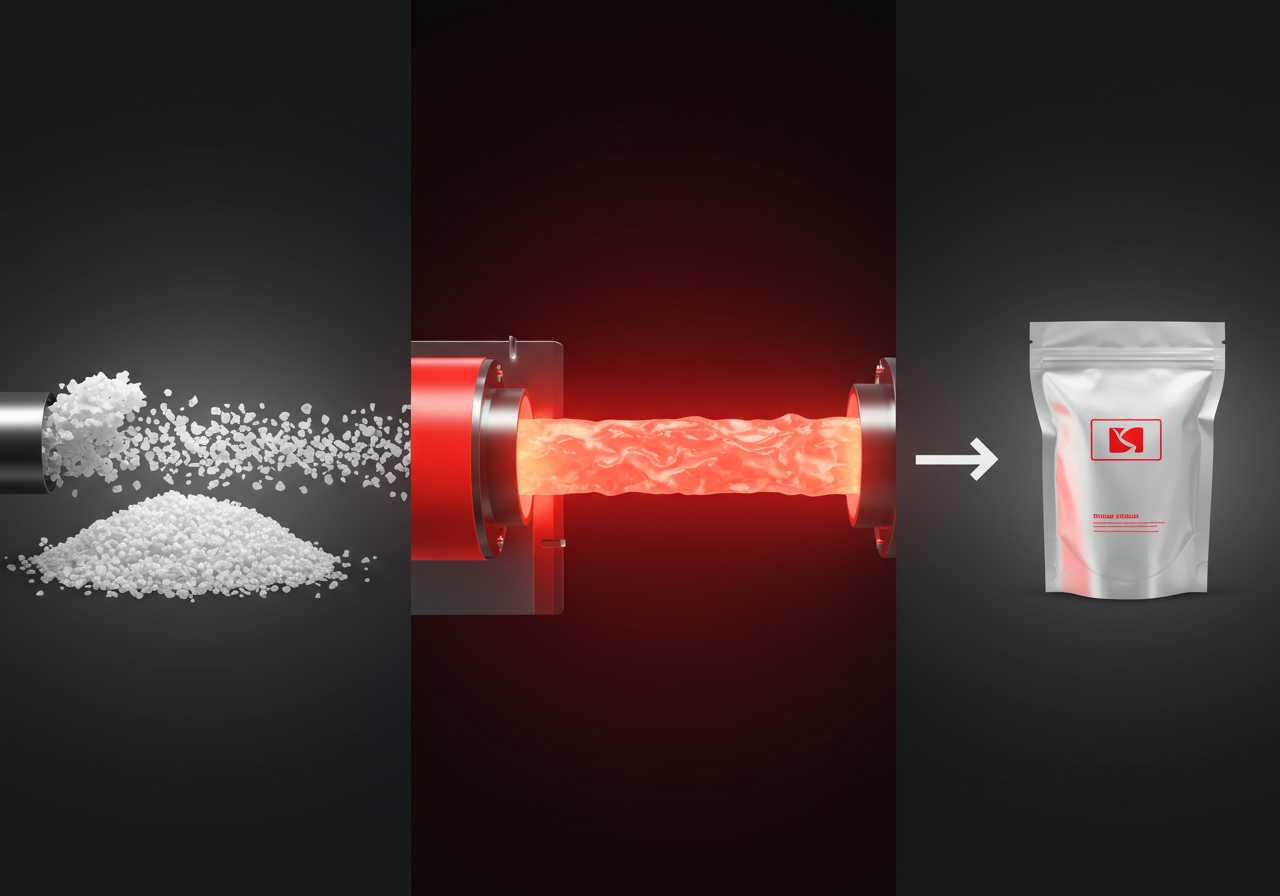

Think of plastic extrusion as a highly advanced, industrial-scale version of squeezing toothpaste from a tube. The process begins with raw plastic pellets, which are fed into a machine called an extruder. Inside, these pellets are melted, mixed, and then forced through a shaped opening (a ‘die’) to form a continuous film. This film is the foundational material for creating a vast array of flexible packaging pouches.

This method is crucial for pouch packaging because it allows us to produce films that are not only strong and flexible but also tailored with specific protective qualities. These films act as a barrier against moisture, oxygen, and light, ensuring products like spices from Hamza Spices or tea from Steps Tea remain fresh from the factory to the consumer’s home.

The Step-by-Step Journey: From Granule to Film

The magic of transforming tiny plastic granules into a durable packaging film involves several precise steps:

- Feeding the Hopper: The process starts when raw plastic pellets, along with any necessary additives like colourants or UV stabilizers, are loaded into a large funnel-like container called a hopper. This hopper carefully feeds the material into the main body of the extruder, ensuring a consistent and steady supply for a smooth operation.

- Melting and Conveying: From the hopper, the pellets enter a long, heated barrel containing a rotating screw. As the screw turns, it propels the pellets forward, and the heat from the barrel walls melts them into a homogenous molten liquid. The screw’s design ensures the plastic is thoroughly mixed and reaches a uniform temperature.

- Shaping Through the Die: The molten plastic is then pushed through a specially designed die at the end of the barrel. The shape of this die determines the final form of the plastic. For pouch manufacturing, a flat die is typically used to create a thin, wide sheet or film.

- Cooling and Solidification: Once the hot plastic film exits the die, it must be cooled rapidly to solidify and set its shape. This is usually achieved by passing it over a series of chilled rollers or through a controlled air-cooling system. Proper cooling is vital for achieving the desired clarity and strength in the final film.

Types of Extrusion for High-Performance Pouches

Different packaging requirements call for different types of films. As an experienced laminated pouch maker, we utilize various extrusion methods to meet client needs:

- Blown Film Extrusion: This technique involves extruding the plastic upwards into a tube and then inflating it with air like a balloon. This process stretches the film in two directions, giving it balanced strength and making it ideal for bags and pouches that need to be tough and resistant to tearing.

- Cast Film Extrusion: In this method, the molten plastic is extruded directly onto a large, chilled roller, which quickly cools and solidifies it into a flat sheet. Cast films are known for their exceptional clarity, uniform thickness, and high gloss, making them perfect for premium packaging where visual appeal is paramount.

Often, we use co-extrusion, a process where multiple layers of different polymers are combined into a single film. This allows us to create multi-layered structures, like a two-layer laminated pouch, that offer a combination of benefits, such as strength, printability, and superior barrier protection.

Tirupati Traders: Your Partner for Custom Packaging Solutions

Understanding the science of plastic extrusion allows us to be more than just a manufacturer; we are your strategic packaging partner. For businesses across India and for our export clients, we deliver packaging that performs. Whether you need a durable packet for detergent powder or a hygienic pouch for sanitary products, our process is tailored to you.

Many clients want to know if they can truly customize their packaging. The answer is yes. By adjusting the polymers, additives, and extrusion method, we can create packaging that is perfectly suited to your product. For instance, for our client Kanupriya Namkeen, we developed a specialty snacks pouch with high clarity and excellent moisture barrier properties to ensure their products stay crispy and delicious, enhancing both shelf life and brand appeal.

Meeting Diverse Industry Needs

The versatility of plastic extrusion means we can serve a wide range of industries with precision-engineered solutions:

- Food & Beverage: From banana chips pouches to packaging for whole spices, our films provide the necessary barrier to keep food fresh and safe. We ensure that the materials used are food-grade and meet all safety standards.

- Personal Care: We create aesthetically pleasing and functional pouches for products like sanitary pads and cosmetics, offering hygienic and secure packaging. Our printed sanitary pad pouches are designed for discretion and durability.

- Industrial & Agricultural: For products like detergents, fertilizers, or hardware, we manufacture robust plastic laminated pouches that can withstand tough handling and protect the contents from environmental factors.

Innovating for a Sustainable Future

A common question we receive revolves around the environmental friendliness of plastic extrusion. As a forward-thinking custom printed pouch manufacturer, we are committed to sustainability. The industry is rapidly evolving with innovations like using post-consumer recycled (PCR) plastics, developing bio-based polymers from plant sources, and engineering thinner yet stronger films to reduce overall plastic consumption. These advancements are helping us create packaging that is both effective and more responsible.

The Final Word

Plastic extrusion is a remarkable and highly technical process that is fundamental to modern product packaging. It provides the flexibility, strength, and protection that brands need to succeed. At Tirupati Traders, we have mastered this process to deliver packaging that not only meets but exceeds expectations.

If you are looking for a reliable packaging partner to elevate your brand, we are here to help. Call us at +91 70032 13441 to discuss your custom packaging requirements today!