In the bustling marketplace of India, your product’s packaging is its first handshake with the customer. It’s more than just a container; it’s a promise of quality, safety, and brand integrity. For industries like FMCG, food and beverages, agriculture, and pharmaceuticals, this promise is non-negotiable. This comprehensive guide delves into the world of packaging testing and quality assurance, explaining why it’s critical for your business and how you can achieve packaging excellence with a reliable packaging supplier like Tirupati Traders.

Why Your Packaging’s ‘Final Exam’ Matters More Than You Think

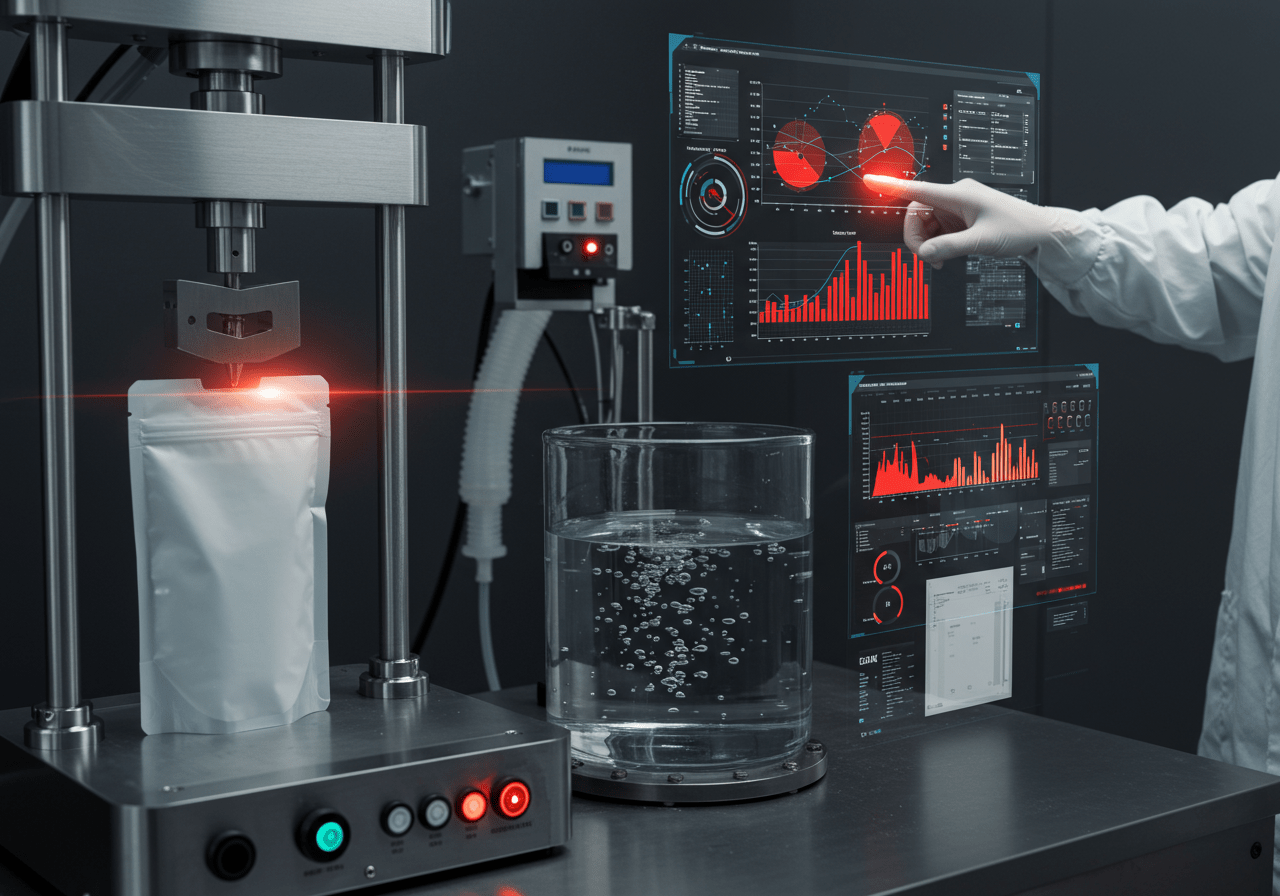

So, what exactly is packaging testing? Think of it as a series of rigorous examinations that your packaging must pass to prove it can protect your product effectively. This process evaluates everything from material strength and durability to its ability to shield contents from external factors. For any business, understanding the importance of quality assurance in packaging is fundamental. It ensures that every pouch, bag, or packet leaving your facility meets specific standards, providing a consistent and trustworthy experience for your customers. This meticulous process helps prevent costly issues like product damage during transit, contamination, leakage, or spoilage, safeguarding both your investment and your brand’s reputation.

In a competitive landscape, robust quality checks are not just a regulatory hurdle but a strategic advantage. They ensure you avoid legal complications, build unshakeable consumer trust, and manage costs by preventing recalls and waste. As consumers become more eco-conscious, testing for sustainability and recyclability has also become a key part of building a modern, responsible brand image.

The Core Pillars of Packaging Testing: What Gets Measured

To ensure packaging is fit for purpose, it undergoes several types of tests, each designed to challenge its limits. As a leading laminated pouch maker, we know these tests are crucial for guaranteeing performance.

- Mechanical Strength and Durability Tests: These evaluations determine how well your packaging can handle the rough and tumble of the supply chain. This includes drop tests to simulate accidental falls, compression tests to check its stacking strength in warehouses, and vibration tests to mimic the stresses of road transport in India. The goal is to ensure your product arrives in perfect condition, no matter the journey.

- Barrier and Seal Integrity Tests: This is especially critical for food and pharmaceutical products where freshness is paramount. Barrier testing measures the packaging’s ability to protect against moisture, oxygen, and light, which can degrade product quality. Seal integrity tests, using methods like vacuum decay or pressure tests, confirm that seals are airtight to prevent leaks and contamination, keeping products like our moisture-proof salt packaging secure.

- Material and Product Compatibility Tests: It’s vital to confirm that the packaging material itself doesn’t react negatively with the product it holds. Chemical compatibility tests ensure there is no leaching of harmful substances into the product, preserving its purity, taste, and safety. This is a standard check for items ranging from spices to fertilizers.

- Environmental and Aging Simulation: These tests predict how your packaging will perform over time and under various climatic conditions. Accelerated aging tests simulate long-term storage, while environmental chambers expose the packaging to extreme temperatures and humidity. This ensures your product remains stable and safe, whether it’s stored in a cool warehouse or a humid retail shop.

A Step-by-Step Approach to Flawless Packaging Performance

Achieving consistently high-quality packaging requires a systematic approach. From initial design to final production, every step is an opportunity to build in reliability and performance. Many businesses wonder how they can improve their packaging quality, and the answer lies in a structured, proactive process.

The journey often begins with selecting the right materials. Whether you need flexible polymers for two-layer laminated pouches or robust structures for heavy-duty bags, the material choice is foundational. After design and prototyping, a crucial phase of pre-production testing helps identify potential flaws before a full-scale manufacturing run, saving time and resources. Continuous in-line quality checks during production and rigorous post-production sampling ensure that every batch meets your brand’s high standards. For an extra layer of confidence, engaging a third-party accredited lab can provide unbiased validation of your packaging’s performance. Furthermore, it’s important to remember that packaging should be re-tested whenever there are significant changes to the product, materials, or production scale to maintain ongoing reliability.

Navigating the Maze of Indian and Global Regulations

Compliance is not just about following rules; it’s about ensuring your product is safe and marketable. In India, standards set by bodies like FSSAI (Food Safety and Standards Authority of India) are critical for food packaging, while international standards like ISO, ASTM, and ISTA govern everything from pharmaceutical packaging to transport durability. Properly documented testing procedures are your best defense during an audit. This verification process ensures that your packaging meets all legal requirements, helping your business avoid hefty fines and recalls while building invaluable trust with consumers and partners alike.

Partnering with Tirupati Traders for Assured Quality

Choosing the right partner is crucial for navigating the complexities of packaging testing and quality assurance. At Tirupati Traders, we are more than just a custom printed pouch manufacturer; we are your partners in quality. We provide high-performance, customizable packaging solutions that help businesses across the FMCG, food, agro, and pharma sectors meet and exceed their quality goals.

Our commitment to excellence is reflected in our products:

- Premium, Durable Materials: We use top-grade materials to craft packaging that excels in durability, moisture resistance, and seal integrity. Our paneer packaging pouches are designed to guarantee freshness, while our detergent powder packets offer robust protection and brilliant branding.

- Tailored to Your Needs: Every product is unique, and so are its packaging requirements. We offer a wide array of customizable solutions, from stylish and convenient glossy zipper pouches to hygienic and secure sanitary pad pouches, all designed to align perfectly with your brand and product specifications.

Case Study: Enhancing Brand Trust for Hamza Spices

When Hamza Spices, a growing name in the Indian market, wanted to launch a new line of premium spices, they needed packaging that not only looked good but also provided superior protection. They partnered with us to develop a custom-branded laminated pouch. Our team ensured the material passed stringent barrier tests for moisture and oxygen, and seal integrity tests to lock in the aroma. The result was packaging that preserved the product’s quality and boosted consumer confidence, helping Hamza Spices secure a stronger market position.

The Final Wrap-Up: Your Commitment to Excellence

In conclusion, packaging testing and quality assurance are fundamental pillars supporting your product’s journey from production to the consumer’s hands. It’s an investment in your brand’s reputation, customer loyalty, and long-term success. By understanding the key tests, following a systematic quality process, and partnering with an expert packaging supplier like Tirupati Traders, you can ensure your packaging is not just a container, but a competitive advantage.

Ready to elevate your packaging? Contact us today to explore our wide range of high-quality, reliable packaging solutions tailored for your business.